Accoya Approved Manufacturer VA

Specify Accoya

“Acetylated lumber wins accolades for its performance and small environmental footprint” ~ Green Building Advisor

Unlike most pressure-treated wood, acetylated lumber doesn’t contain any copper or biocides that can leach into the environment over time. The treatment renders the wood harder, more dimensionally stable and immune to insects. Accoya lasts for 50 years above grade, 25 years in contact with the ground or submerged in fresh water, and has a service life of 70 years, according to its manufacturer.

Build From the Foundation

You understand the metaphor if you’re a builder. We are limited in our ability to deliver a ‘straight’ product, by straight lumber! In order to deliver your dream piece, we need quality lumber that will not warp or twist and it is becoming harder to source. Just like you wouldn’t want your foundation to be 1/8th out of square, we don’t want our raw materials to move 1/8th of an inch after they are machined to size.

Acetylation BY ROGER M. ROWELL ~ 4 SEPTEMBER 2006

The Vikings burned the outside of their ships to make them water resistant and flame retardant without knowing anything about hydrophobicity or the insulating properties of char!

Long before we had formal wood science, we had a long history of observations on the properties and performance of wood. It was well known that wood swelled and shrunk with water, that wood decayed, that wood burned, and that wood was degraded by the sun. People took advantage of the positive properties and also learned to design around wood’s weaknesses. As we started to understand the properties and performance of wood, we discovered that the properties of wood are, for the most part, a result of the chemistry of its cell wall components.

From this foundation, the science of chemical modification of wood was born. We first learn by observation, progress by experimentation, and finally advance through understanding. We learned to use wood, accepting that it changes dimensions with changing moisture content (MC),

Chemical modification of wood can be defined as a process of bonding a reactive simple chemical to a reactive part of a cell wall polymer, with or without catalyst,

to form a covalent bond between the two. Chemical modification of wood has historically been used to:

1) isolate various cell wall components;

2) study differences in properties as a result of changing the chemistry;

3) improve the performance properties of wood.

Many chemical reaction systems have been published for the modification of wood and the systems have been reviewed in the literature. The chemicals include anhydrides, acid chlorides, ketene carboxylic acids, isocyanates, formaldehyde, acetaldehyde, difunctional aldehydes, chloral, phthaldehydic acid, and epoxides .

None of the studies of the chemical modification of wood and other lignocellulosic resources have gone past the research stage, except acetylation.

Read Full Article

“Our sales in North America increased by 44% between fiscal years 2021 and 2022, and we continue to see strong demand for Accoya,” said John Alexander, group sales director. “Once operational, our Accoya 2022 production volumes will be doubled at the Kingsport site.”

The Kingsport facility, which will be operational in early 2024, will provide the North American market, while the Netherlands plant will supply the rest of the world. The American reactors are now on their way from Europe and will arrive in Kingsport in January 2023.

“We are excited to be a part of the Kingsport community and watch the development of the US facility,” said Rod Graf, general manager of Accoya USA. “Our cutting-edge building materials will enhance capacity, create local jobs, and foster community. We are also eager to work with the Tennessee College of Applied Technology and the Regional Center for Advanced Manufacturing to become a preferred employer in the region as production begins.”

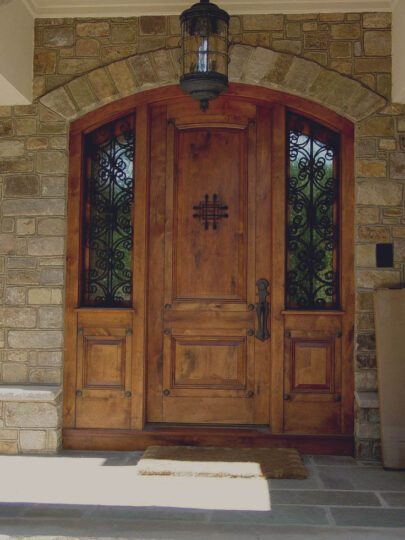

Accoya Acetylated Project Gallery