Choosing the Right General Contractor for a Historic Renovation or Fix-and-Flip in Richmond, Virginia

Richmond, Virginia, is a city steeped in history, with neighborhoods that showcase architectural styles from the late 18th century through the early 20th century. For homeowners, real estate investors, and architects, this makes Richmond a prime location for historic renovation projects and fix-and-flip opportunities. Whether you are breathing new life into a Church Hill rowhouse or restoring a Victorian in The Fan District, one of the most critical decisions you’ll make is choosing the right general contractor.

But a contractor is just one part of the puzzle. Your project will only succeed if the materials match the home’s original design and construction methods. That’s where Gepetto Millworks comes in. Based in Virginia, Gepetto is not a general contractor, but they supply historically accurate windows, doors, and millwork, along with consulting expertise, to ensure that your contractor and architect deliver a result that preserves the property’s charm and historic value.

This guide covers everything you need to know about:

- How to choose a good general contractor in Richmond for a historic renovation

- Key factors for fix-and-flip investors to maximize ROI while preserving character

- Why historically accurate building materials matter for long-term value

- How Gepetto Millworks partners with contractors, architects, and homeowners to create historically faithful results

Why Historic Renovation Requires a Different Approach

Renovating a historic home is not like doing a typical remodel. Richmond’s historic neighborhoods are filled with properties that are over 100 years old. Many of them feature construction techniques that are no longer common today, including:

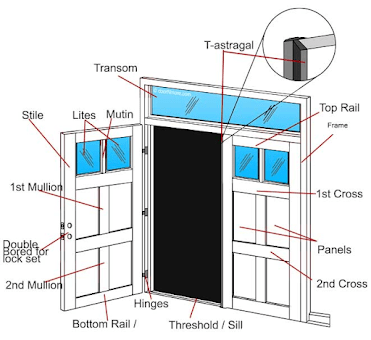

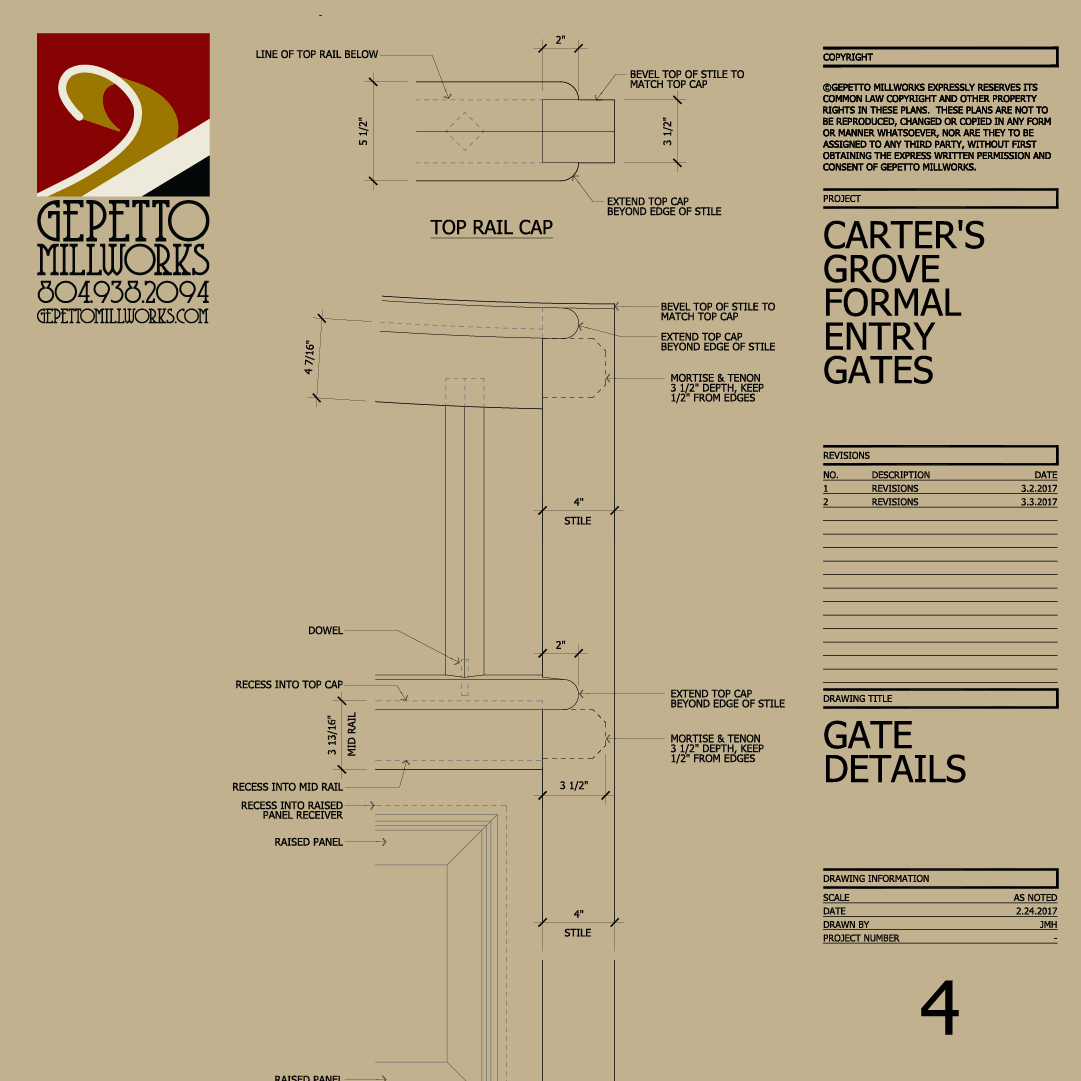

- Mortise-and-tenon joinery in window sashes and door frames

- Solid wood construction using species like heart pine, oak, and sapele

- Custom molding profiles that cannot be replicated with standard stock trim

- True divided-light windows that require proper glazing techniques

- Plaster and lath walls instead of modern drywall

Your contractor must understand how to work with these materials and techniques—or at least know when to call in specialists. A contractor who simply rips out old windows and installs vinyl replacements may make the house less valuable, both historically and financially.

The Richmond Neighborhoods Where Historic Renovations Shine

When planning your renovation, it’s worth considering the context of Richmond’s historic neighborhoods, each of which has its own character:

- Church Hill – Richmond’s oldest neighborhood, full of Federal, Greek Revival, and Italianate rowhouses.

- The Fan District – Known for its Victorian, Queen Anne, and Colonial Revival townhomes with elaborate woodwork.

- Jackson Ward – Once known as the “Harlem of the South,” this neighborhood is rich in African American history and 19th-century architecture.

- Ginter Park – Early 20th-century homes with wide porches, Craftsman detailing, and unique wood features.

- Woodland Heights and Forest Hill – Bungalows and foursquare houses with unique exterior millwork.

A contractor with experience in these neighborhoods will already be familiar with Richmond’s historic district guidelines, zoning requirements, and common renovation challenges.

Step-by-Step Guide to Choosing a General Contractor

1. Look for Historic Renovation Experience

A contractor who has done kitchen remodels in modern homes may not be the right fit for a 1900s Victorian. Ask potential contractors to show you examples of past projects specifically involving historic properties. One fun element to work from are historic pictures, did they use historic reference and research in their design decision making?

2. References Return our Humanity

Request references from other clients, ideally those who have renovated homes in Richmond’s historic neighborhoods. No construction project goes perfectly, so it’s more valuable to have a contractor that will bring issues to light, discuss and resolve instead of shuffling under the carpet or taking shortcuts.

3. Check Their Relationships with Specialists

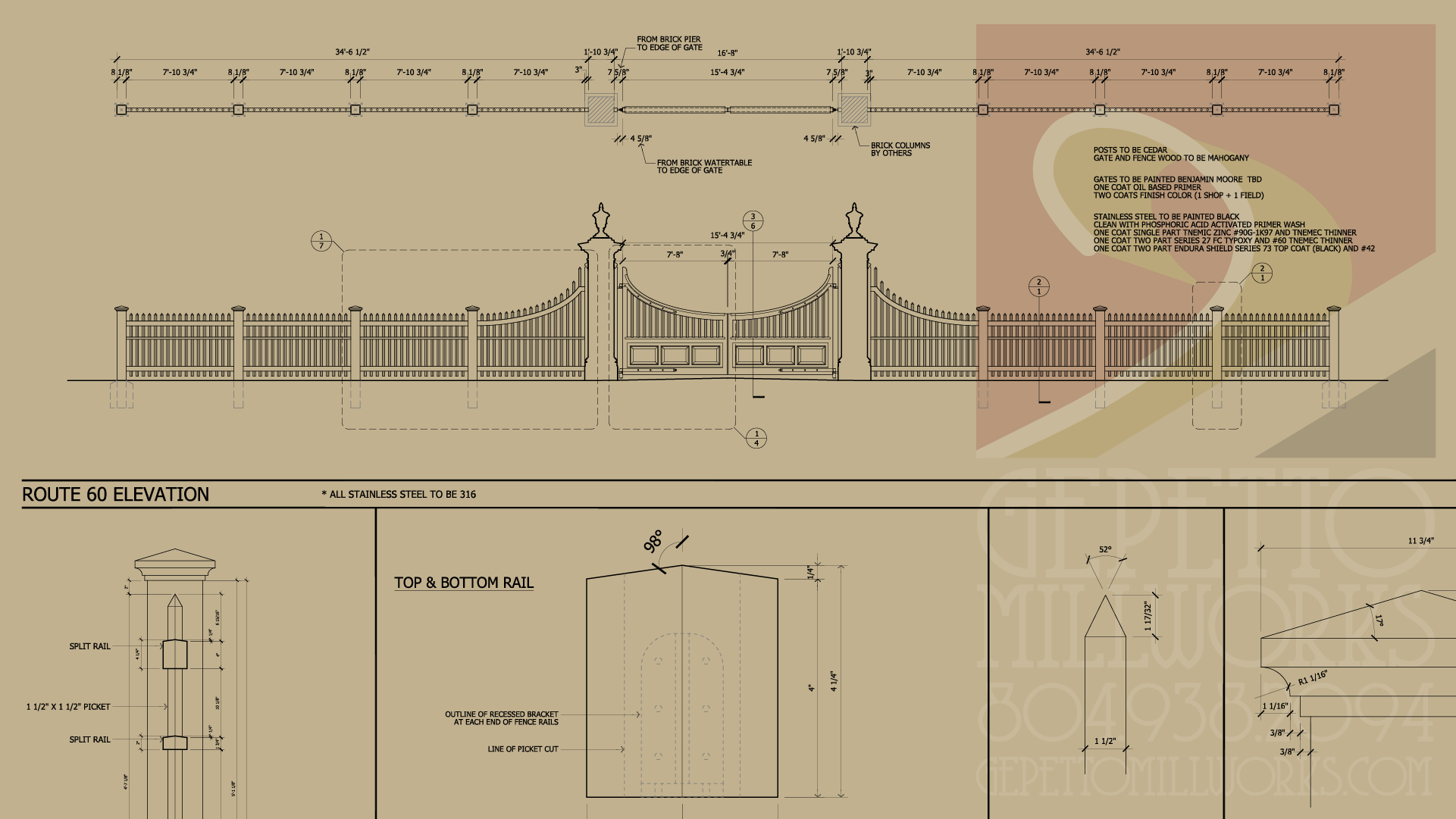

Many contractors will need to partner with specialists such as plasterers, wood window restoration experts, and millwork suppliers like Gepetto. Ask whether they have established relationships with these subcontractors and trades. See the video below for reference about how Matthew Wiley, the ‘wood’ expert – brought a masonary element into question in the drawing stage to unify the design around the windows. Collaboration builds.

4. Ask About Communication and Project Management

Historic renovations can uncover surprises—hidden damage, outdated wiring, or structural issues. Choose a contractor who communicates clearly, documents changes, and can coordinate with your architect to turn an unexpected upset into a success. We have seen to many of these problems attempted to be buried, and they will only come back to haunt you. It’s a common mis-conception that a contractor provides a ‘quote’ of a fixed price – that is ‘all in’. You need to choose a contractor willing to build the trust and communication to weather changes. Payment schedules in professional contracts are not ‘half upfront’ they include healthy milestones and checkoffs for each stage of the build. If you read online, you’ll see the sad stories of those that were quotes the lowest price and ‘paid half upfront’.

5. Get a Written Proposal and Timeline

Historic projects can take longer than anticipated, so set clear expectations up front. A good contractor will provide a detailed written proposal and realistic timeline. Professional contracts have milestones that break the project into smaller pieces, as well as the payment schedule so that you can see your project coming to life as you’re writing incremental checks.

Fix-and-Flip Considerations for Richmond Investors

If you are a real estate investor doing a fix-and-flip project, you face a balancing act: maximizing your return on investment while preserving enough character to attract buyers. Today’s homebuyers in Richmond love properties with original charm. Here’s why working with the right team matters:

- Curb appeal sells homes. Gepetto’s historically accurate windows and doors make a house stand out in a competitive market.

- Buyers notice quality. Solid wood doors, real divided-light windows, and custom trim elevate a property beyond the “builder-grade flip.”

- Historic tax credits may apply. In Virginia, there are state and federal tax incentives for rehabilitating historic properties that can ease the high cost of diving into an historic property.

- Long-term durability matters. Properly restored or replicated elements last longer and reduce call-backs after the sale. If the windows are 100 years old, our exact replicas would be expected to last the same duration with the proper maintenance. Don’t loose sight of the amortization against 100 years, instead of looking only at today’s profit.

Why Historically Accurate Materials Are Crucial

When renovating a historic home, the wrong materials can diminish its value. Vinyl windows, MDF moldings, and hollow-core doors might be cheaper upfront, but they detract from the authenticity of the property. Gepetto Millworks specializes in:

- Sapele solid wood windows built with mortise-and-tenon joinery for century-long durability

- Custom solid wood doors that replicate the proportions and panel profiles of the originals

- Exact-match molding profiles that blend seamlessly with existing trim

- Architectural consulting to ensure every detail is period-appropriate

Collaborating Early with Gepetto Millworks

One of the most effective ways to avoid costly mistakes is to bring Gepetto Millworks into the conversation early. Here’s why:

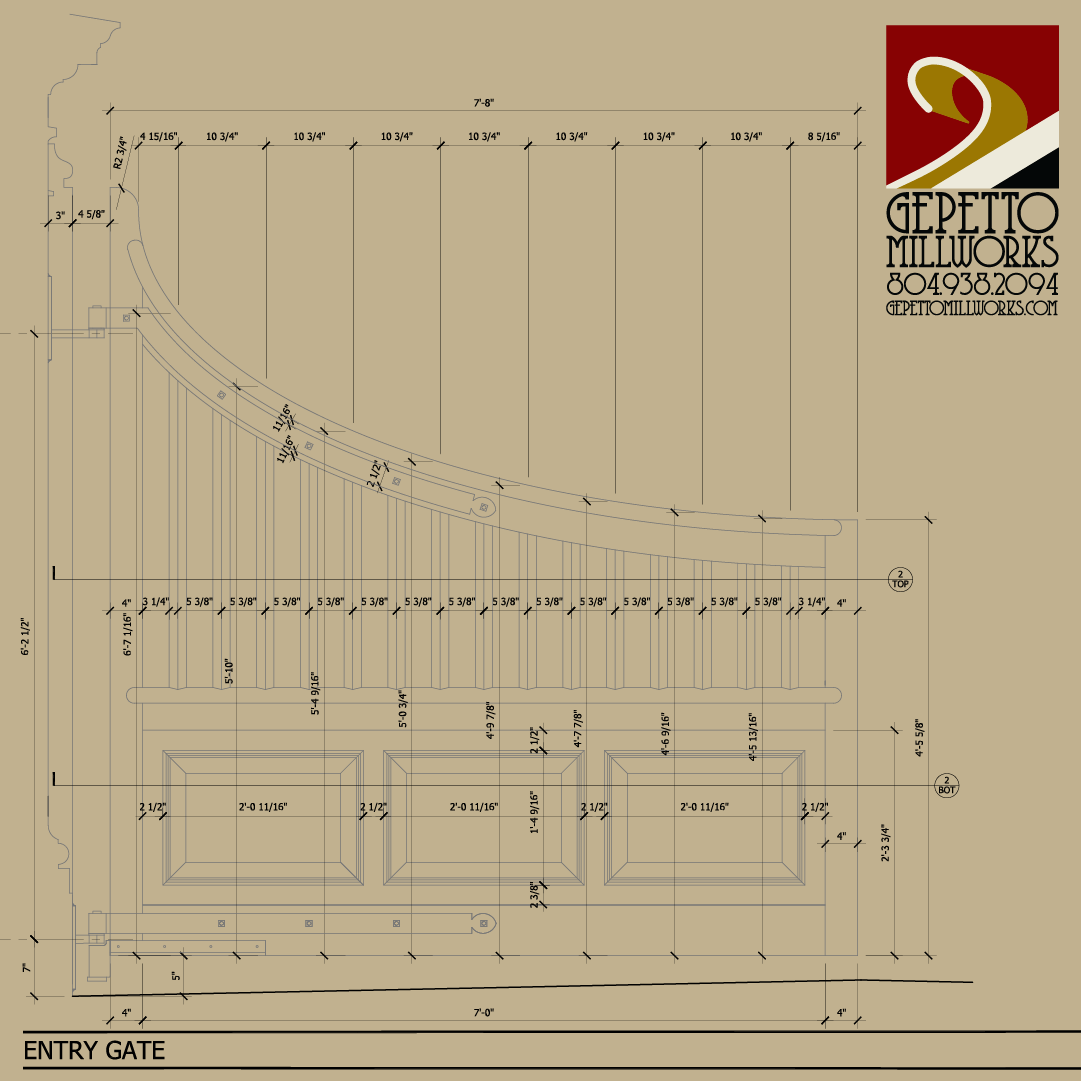

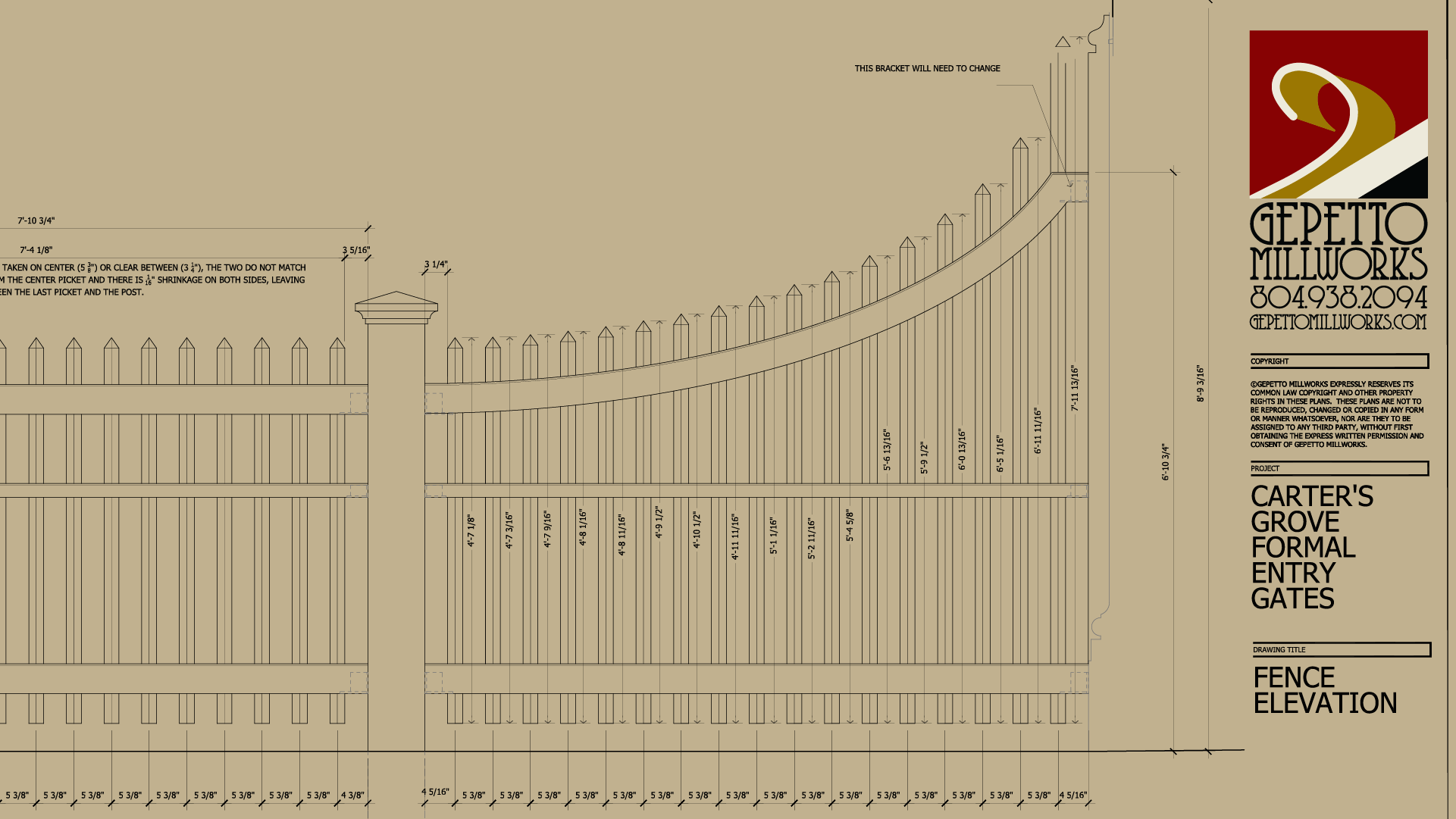

- Pre-construction planning: Gepetto can work with your architect to design historically accurate elements.

- Material lead time: Custom windows and doors take time to fabricate—ordering early keeps your project on schedule.

- Contractor coordination: Gepetto can consult with your contractor to ensure proper installation techniques.

- Cost management: Early dialogue helps balance authenticity with budget.

By calling Matthew Wiley at Gepetto Millworks before your project begins, you establish a partnership that can guide your contractor and architect toward the right choices. His number is 804.8938.2094 and amidst all the spam and promotions you’ll probably be receiving as you google your way through this building journey – Matt is and old fashioned real person on the other end of the line. His 25 years experience in Richmond is a living rolodex of referrals and expertise for you to connect with.

How Gepetto Supports Architects and Contractors

Gepetto doesn’t just supply materials—they act as a technical partner. Their team can provide:

- Shop drawings down to the millimeter for every window and door opening

- Guidance on joinery and wood species to match historical standards

- Advice on finish options to replicate period-appropriate colors and sheens

- Ongoing communication throughout the project

This level of support makes the contractor’s job easier and ensures that the final product meets both the homeowner’s and the historic district’s expectations.

Preservation and Long-Term Value

For homeowners who plan to live in their house long-term, preserving its historic character is not just about aesthetics—it’s about protecting the property’s value. Homes that retain original wood windows, doors, and trimwork consistently sell for more than those that have been stripped of their historic charm.

Additionally, Richmond’s historic districts are a draw for tourism and community pride. By investing in a thoughtful renovation, you are contributing to the cultural fabric of the city.

Getting Started: Your Next Steps

If you’re planning a historic renovation or fix-and-flip in Richmond:

- Research contractors with proven historic renovation experience.

- Schedule consultations and request detailed proposals.

- Contact Gepetto Millworks early to discuss your material needs.

- Start a dialogue between contractor, architect, and supplier to ensure everyone is aligned.

Your first call should be to Matthew Wiley at Gepetto Millworks. He can guide you through material options, introduce you to historically accurate solutions, and set your contractor up for success.

Final Thoughts

A historic renovation or fix-and-flip project in Richmond, VA, is an opportunity to create something beautiful, authentic, and valuable. Choosing the right general contractor is critical, but so is choosing the right partner for your windows, doors, and millwork. With Gepetto Millworks supplying historically accurate materials and offering consulting expertise, your contractor will have everything they need to execute a renovation that honors the past and sets your property apart.

By starting early, collaborating with the right professionals, and insisting on authenticity, you can ensure that your project will stand the test of time—just like the historic homes that make Richmond one of the most charming cities in Virginia.