Solid Wood Door vs. Stave Core Door:

Comparison of two solid wood building methods made in the Geppetto Millworks shop

When choosing between a solid wood door and a stave core door, it is important to understand the distinctions between the two. Both types of doors have their own set of advantages and drawbacks. At Geppetto Millworks, located in Charlottesville, Virginia, we specialize in crafting high-quality solid wood doors and stave core doors that ensure durability, aesthetic appeal, and a lifetime of functionality specified by our clients seeking a multi generational door. A solid wood door is crafted entirely from a single species of wood, traditionally and historically panels joined between main staveswith . Doors made with either method are renowned for their natural beauty, sold sense of weight, and the premium craftsmanship that will last for hundreds of years.

Benefits of Solid Wood Doors

Aesthetic Appeal – A solid wood door provides an unmatched natural beauty with unique grain patterns and textures.

Durability – Solid wood construction offers longevity, especially when properly maintained.

Sound Insulation – Due to their density, solid wood doors provide excellent soundproofing.

High-End Look and Feel – The weight and texture of a solid wood door contribute to a luxurious aesthetic.

Customizability – These doors can be easily carved, stained, or finished in numerous ways to match any design style.

Drawbacks of Solid Wood Doors

Susceptibility to Humidity – Wood expands and contracts with changes in moisture, which can cause warping or cracking.

Weight – The heft of a solid wood door can make it difficult to install and may require additional reinforcement.

Cost – Due to the premium materials used, solid wood doors tend to be more expensive.

Maintenance Requirements – Regular refinishing and sealing may be needed to protect against environmental elements.

Stave Core Doors are also “Solid” So Why Two Terms?

A stave core door is constructed using multiple small wood pieces, glued together and covered with a veneer of high-quality hardwood. This method enhances stability while maintaining the natural look of a solid wood exterior.

Benefits of Stave Core Doors

Greater Stability – A stave core door resists warping and shrinking, making it ideal for fluctuating climates.

Consistent Appearance – The veneer provides a uniform surface without the imperfections often found in natural solid wood.

Drawbacks of Stave Core Doors

Veneer Durability – While the exterior veneer looks like solid wood, it can be susceptible to damage and may not last as long as solid wood if frequently exposed to wear and tear.

*Gepetto does not produce any product with veneer – all our doors are solid wood of greater than 3/8″ thickness. We are writing this to help you decide what is best in your purchasing, and if you are being quoted a veneer product – it’s not the same as our quote. The stave core builds we do are to increase stability and reduce internal warp and twist that can occur in the high humidity of Virginia. At Geppetto Millworks, we offer both types of doors in solid wood to suit your specifications when ordering custom made doors.

Geppetto Millworks: Your Source for High-Quality Solid Wood Doors

At Geppetto Millworks, we have extensive experience crafting both solid wood doors and stave core doors. Our team in Charlottesville, Virginia, uses the finest materials and craftsmanship to create doors that stand the test of time. Whether you are looking for a classic solid wood door or a durable stave core door, we are here to help you make the best choice for your home or business.

For more information, contact us today to explore our wide range of solid wood doors and stave core doors.

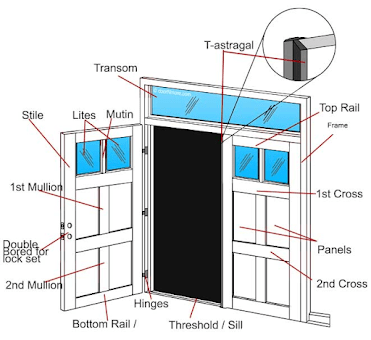

On the left (or above on mobile) you’ll see our technical terms for the parts of a door. The main vertical piece of wood – called the Stile – in all our doors we have to do the detailed foundational work of finding a solid stock of lumber thicker than 2″ and taller than the door. The selection of this piece becomes more complex as any amount of internal pressure in the grain structure can twist and warp your final product. One of the ways we combat the internal twist, is to bond two ‘staves’ together with a marine grade adhesive so any heating or pressure that develops in the solid wood presses back against a hand matched grain structure effectively counterbalancing the internal pressure. Gepetto does not produce any product with a ‘veneer’ but we would use a 3/8″ or 1/2″ thick piece of mahogany – well known to withstand moisture – with a stave core of something less expensive and lighter for the internal staves. The external face of mahogony becomes vacume bonded using the same water resistant and time tested resorcinol.

Vacume Bonding Staves