If you’re looking for a custom live edge piece for your home, office or restaurant we can supply you with any species locally harvested and specially cured for insect removal and long term humidity stability. Gepetto are the most experienced live edge craftsmen contractors in Virginia and Washington DC. Durable, beautiful, organic wood fabricated with the traditional carpentry techniques of mortise and tenon solid wood matched joints used for centuries.

Avoid live edge problems : hire an experienced contractor

Book Matched Live Edge Slabs

Hire a Richmond Live Edge Contractor

Live edge wood materials are a unique naturally occuring building material. An experienced contractor probably does NOT have handling and building experience with this raw natural material. The live edge plank which is not properly prepared can warp in 5 distinct ways:

- bowing: a deformation along the longest length or end to end deformation that would hinder your table or countertop from laying flat. Seen from the edge, the center of the plank rises or falls compared to the ends.

- crooking: (also called wain) describes a deformation along the full length of the slab, but turned toward the edge of the wood. If the slab is a table, the table shape would split along a center seam joint as if one side of the grain structure pulled the other side – but the board remained flat. Seen from above, it’s a left or right turn while the board stays flat.

- kinking: a localized crook, often due to a knot which does not affect the complete length of the live edge slab.

- cupping: describes a wooden warp between the two live edges, in which the edges are higher than the linear center of the wood. Visualized from above the plank is still straight, but the edges have turned up or down so two matched ends would form a wave.

- twisting or winding: describes a distortion in which the four corners do not lie in the same plane. Just like you imagine, but to visualize, the top left of a plank would show an arc if you were to try and match it to the bottom right corner.

Avoid Common Plank Construction Errors with Experienced Craftsmen

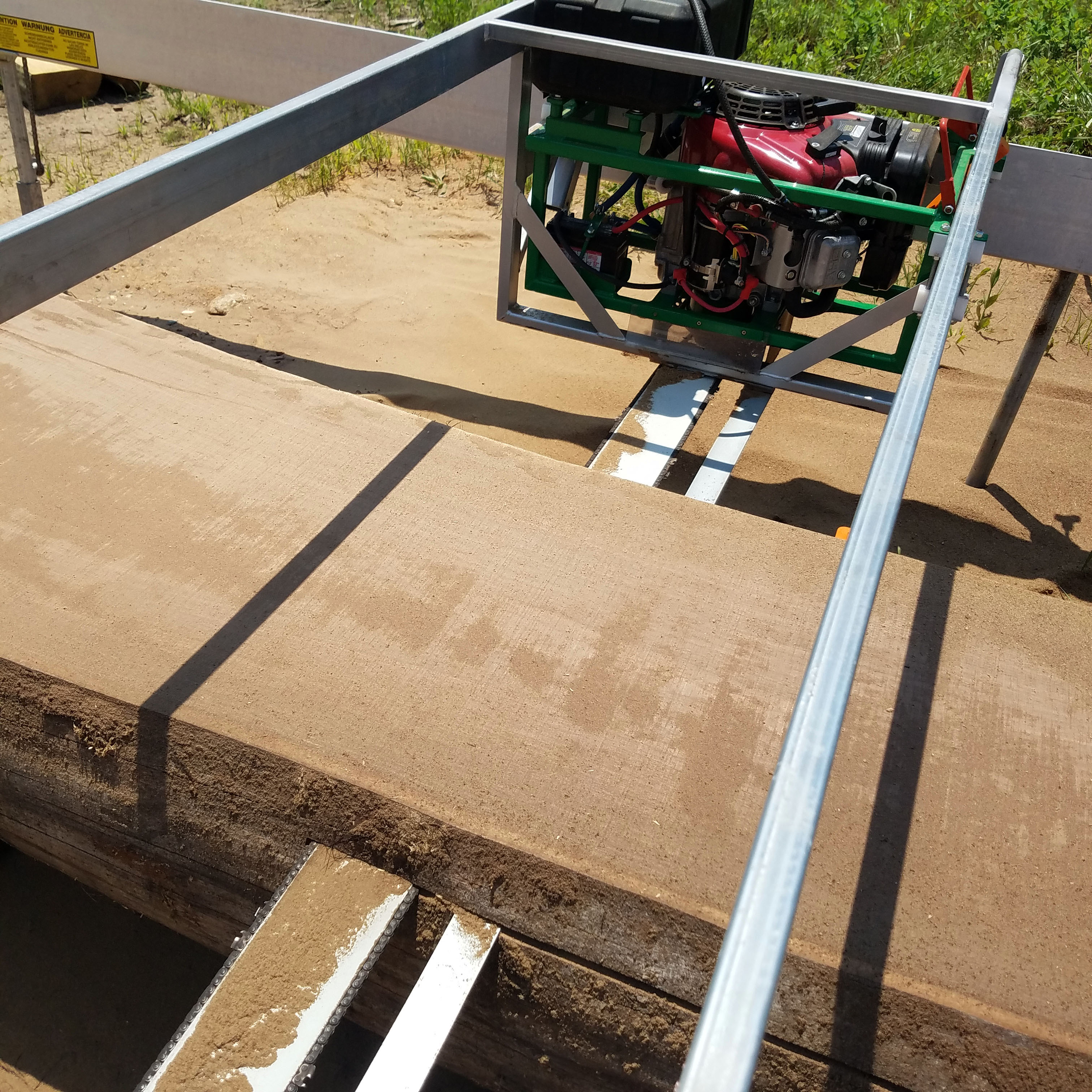

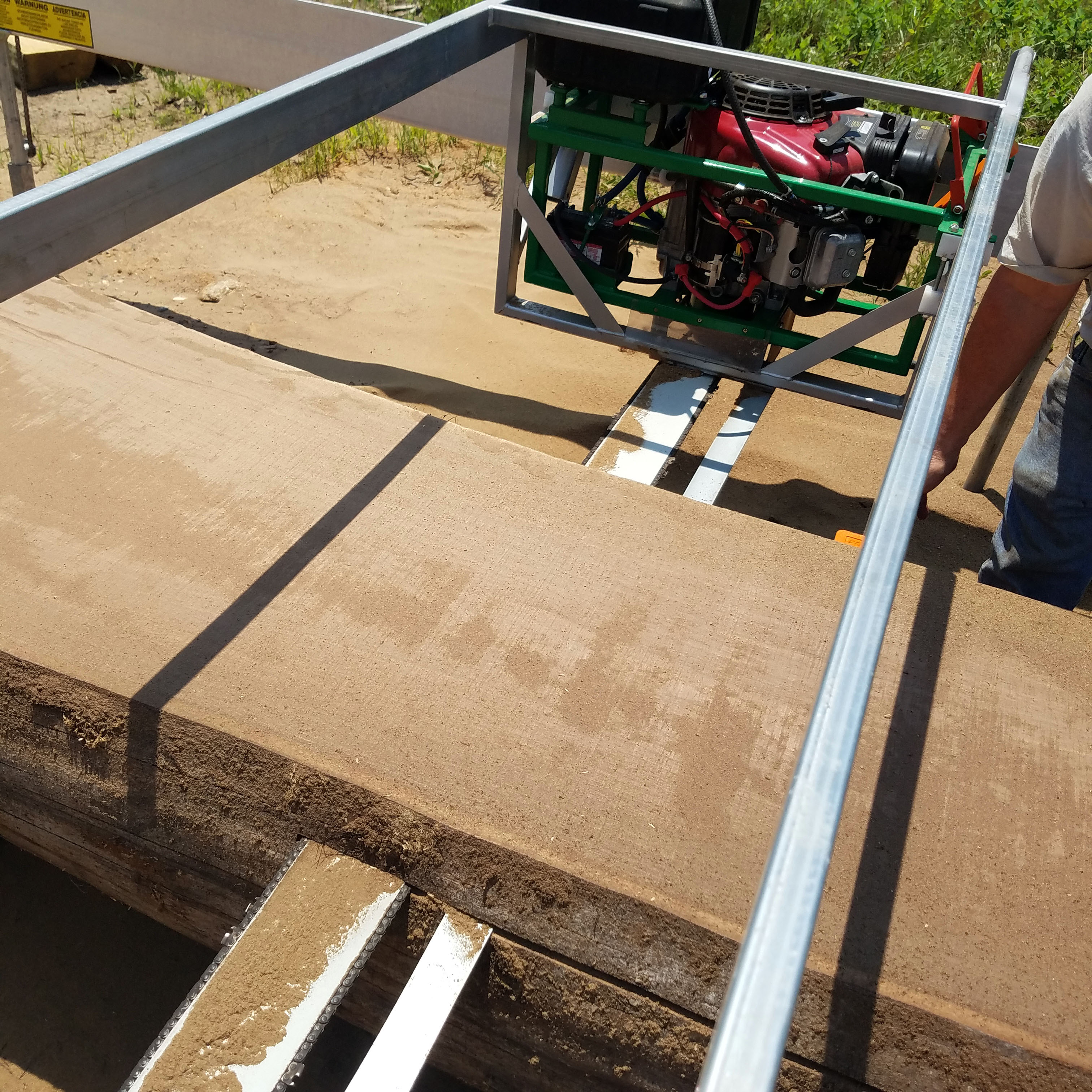

Gepetto craftsmen sort millions of board feet of lumber a year by hand, and by eye. They can spot and feel potential for kinking and will perform the necessary cutting to release the tension in the wood grain itself – and then use that slab for a different project. Most of the expense in a book matched piece is the time and effort to source the right material. Virginia forests have produced a rich variety of species with delightful growth patterns (producing grain structure) and Gepetto Craftsmen have specialized tools for harvesting down trees.

Call Gepetto To Harvest Storm Fallen Trees

Our specialized saw is portable for on-site work. We can harvest ancient wood from urban lots so call us before the city turns it into waste product. We can ‘reclaim’ that wood for use in countertops, windows, doors, benches, tables, and resell it to furniture makers across the mid-atlantic states. Experienced furniture craftsmen come to us to mill the finest lumber or freshest fallen trees.

Live Edge Slab Contractor Virginia https://gepettomillworks.com/t/live-edge

Live Edge Slab Contractor Virginia https://gepettomillworks.com/t/live-edge

Live Edge Slab Contractor Virginia https://gepettomillworks.com/t/live-edge

Live Edge Slab Contractor Virginia https://gepettomillworks.com/t/live-edge

Live Edge Slab Contractor Virginia https://gepettomillworks.com/t/live-edge

Live Edge Slab Contractor Virginia https://gepettomillworks.com/t/live-edge